SYMMETRICAL SPINNAKERS

S3 — Medium Air Reaching

Built for moderate winds and tighter reaching angles, the S3 delivers controlled power when conditions get breezier. Optimized for apparent wind angles 70–130° and 10–20 knots with a flatter shape and heavier cloth to handle increased loads.

Why add an S3?

Reaching spinnakers are flatter than running chutes to reduce heeling at tighter wind angles. While an S3 has the same area as an S1, the material on the S3 is heavier in order to stand up to the greater loads from higher winds. The S3 provides controlled power for medium air reaching conditions when your all-purpose chute starts to overpower the boat.

Flatter Profile

Mid-girth 85–95% of foot

Reduced shoulders and a flatter shape minimize heeling at tighter reaching angles while maintaining excellent projected area for medium air conditions.

Heavier Cloth

0.75 oz. to 0.9 oz. nylon

Built with medium to heavy cloth to offset the greater heeling loads at tighter wind angles and higher wind speeds without sacrificing sail shape.

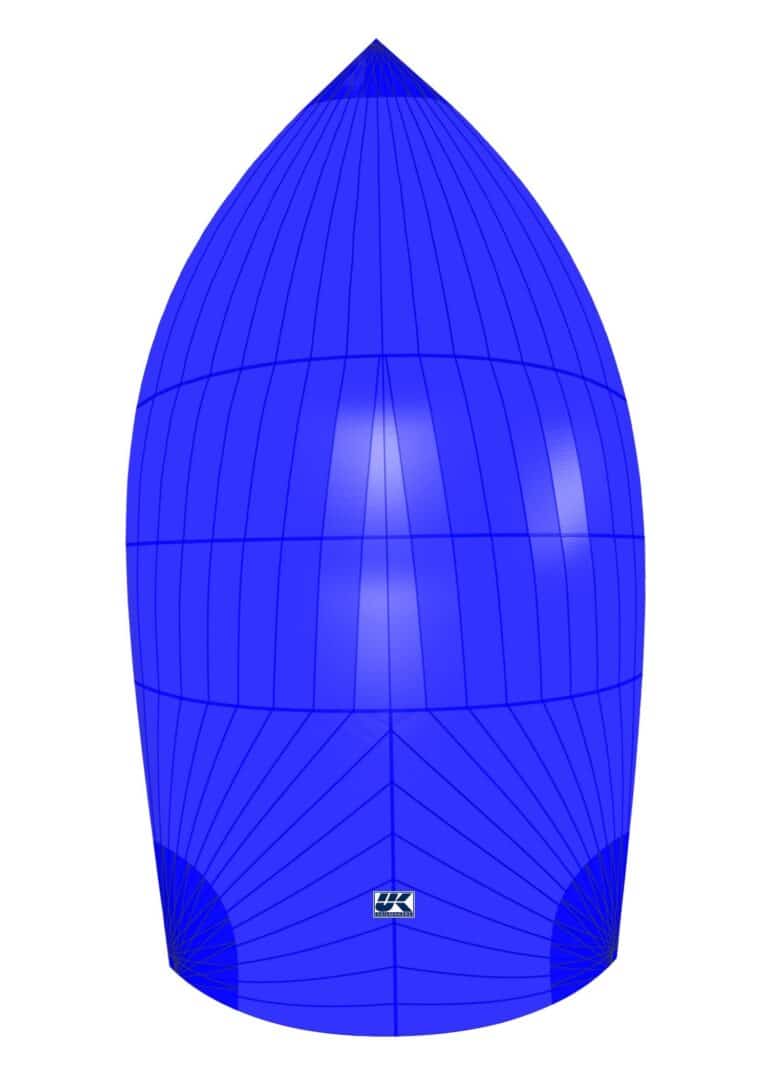

Matrix Construction

Full radial panel layout

Narrow panels oriented to align cloth threads with primary load-paths reduce distortion and create the strongest sail for its weight.

Performance Nylon Technology

The heart of faster spinnakers is the construction method. The panel layout UK Sailmakers uses is called Matrix, which is a full radial layout that features narrow panels, each oriented to better align the threads in the cloth with the primary load-paths in the spinnaker. This is the most effective way to reduce distortion and make the strongest sail for its weight.

Each panel is shaped on all four sides in order to create a smooth round sail. For one sail to be so versatile, it needs to hold its shape without distorting. Distortion becomes most obvious when close reaching. Spinnakers made with generic nylon cloth stretch in the middle, causing their leeches to harden or hook; which reduces driving power, creates drag, and increases heeling. The only way to prevent distortion, without using too heavy a fabric, is to use performance nylon spinnaker cloth like those made under the Superkote and Airx names. These materials have the same strength and stretch resistance of one weight heavier standard nylon.

Spinnaker Painting Program

Use this program to create a custom look for your new spinnaker or cruising spinnaker. Click here to go to the Spinnaker Painting Program.

FAQs

What’s the difference between an S3 and an S1?

While an S3 has the same area as an S1, the S3 features a flatter profile (85-95% mid-girth) and heavier cloth (0.75-0.9 oz vs. 0.5-0.6 oz) to handle tighter reaching angles and higher wind speeds without overpowering the boat.

When should I use an S3 instead of my all-purpose spinnaker?

Deploy the S3 when wind speeds increase to 10-20 knots and you’re sailing at apparent wind angles of 70-130°. The flatter shape and heavier cloth reduce heeling while maintaining excellent reaching performance.

What makes UK’s Matrix construction better?

Matrix uses a full radial panel layout with narrow panels oriented to align cloth threads with primary load-paths. Combined with performance nylon (Superkote/Airx), this prevents mid-sail stretch and leech distortion that rob power and increase drag.