It’s one of the oldest truths in sailing: you get what you pay for. Many cruising sailors choose Dacron sails for their affordability, durability, and classic all-white look. But here’s the catch—not all Dacron sailcloth is created equal.

What makes one Dacron superior to another comes down to three factors: the yarns used, the weaving method, and the finishing processes. A 2020 UK Sailmakers study using Fluid Structural Interaction (FSI) computer simulation study shows that even from the first time you sheet in a sail, low-quality Dacron stretches significantly more than premium cloth.

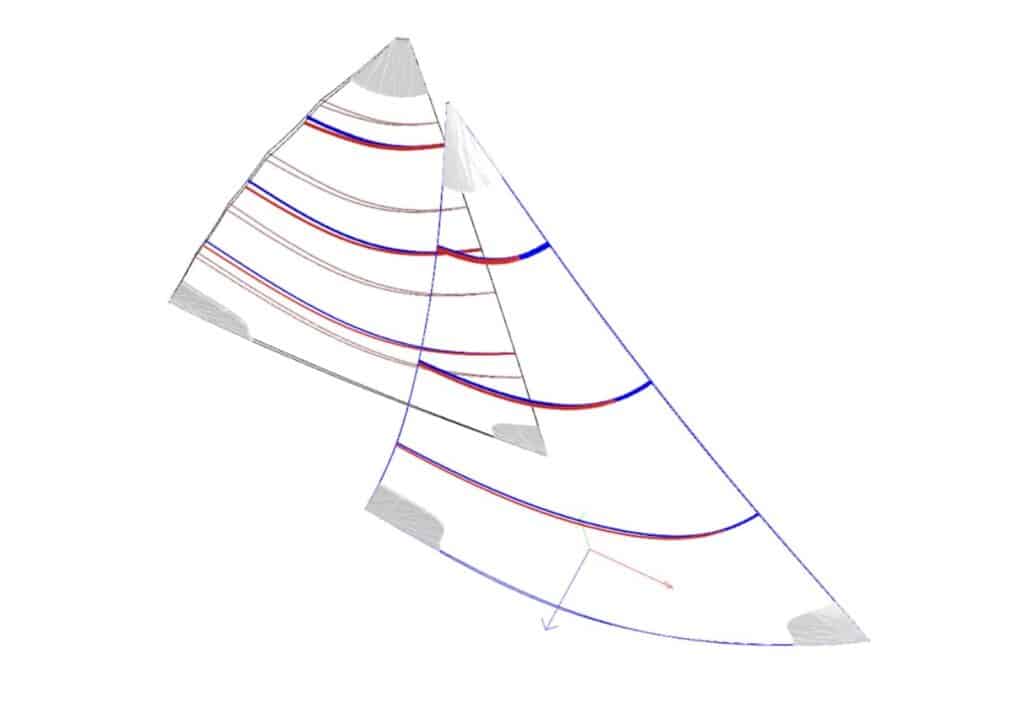

The simulation compared two new crosscut mainsails for a 36-footer—one with inexpensive Dacron and one with premium Dacron. The budget sail stretched up to a third more right out of the bag. Extrapolate that over years of sailing, and the shape loss adds up fast.

You may pay more upfront for a quality Dacron sail from UK Sailmakers than for a bargain sail from a price-driven sailmaker using in-house woven cloth. But those savings are short-lived—cheap sails stretch out, lose shape, and demand replacement far sooner, costing more in the long run while delivering less performance and comfort.

Dacron Sail Terminology

Crosscut Sails

Built with horizontal panels, crosscut sails are cost-effective and popular among cruisers. The sail panels are cut so that the stronger fill yarns align with the vertical loads along the luff and leech, while the warp yarns run across the sail to provide lateral stability. This design is ideally matched with fill-oriented cloth.

Radial Sails

Constructed with a tri-radial layout where panels radiate from the corners (head, clew, tack), aligning the sailcloth to distribute loads from these points. Radial sails offer superior shape retention but come at a higher construction cost.

Weight (in Oz)

A common way to categorize Dacron sailcloth is by its weight, typically expressed in the USA as ounces per sailmaker’s yard (a 36″ x 28.5″ unit of area). In metric terms, grams per square meter (g/m²) is used instead. Heavier cloth generally means increased durability and resistance to stretch, but also adds weight and bulk. Two sailcloths described as the same weight may perform very differently depending on yarns, weave, and finishing—so weight alone doesn’t tell the full story.

High-Aspect vs. Low-Aspect

Dacron sailcloths are tailored to match rig proportions. High-aspect Dacron is designed for tall, narrow sails where loads run predominantly vertically; low-aspect Dacron is engineered for short, wide sails where loads are distributed more evenly across the sail. Choosing the wrong cloth for a high or low-aspect sail can accelerate stretch and reduce the sail’s effective lifespan.

Fill-Oriented Cloth

Designed for cross-cut sails, this cloth features stronger, thicker, fill yarns that run vertically up the sail to handle the primary load paths. The warp yarns, which run lengthwise in the sailcloth roll, run horizontally across the width of the sail, providing lateral stability.

Radial Cloth

Essential for radial sails, this cloth uses high-tenacity (strong, low-stretch) yarns in both directions. Warp-oriented cloth, aligns the strongest yarns with the primary load paths from the corners. Some radial cloths are more balanced to provide high strength in both directions for multi-angle loads.

Square-Weave Dacron

This premium fabric features high-tenacity yarns in both warp and fill directions, creating a grid-like structure. It offers exceptional strength and stretch resistance by weight, making it a top Dacron choice for racers bound by one-design class rules. While it can be loud when luffing, its superior durability and shape-holding make it an excellent investment, particularly for mainsails.

Understanding Dacron: The Three Variables

1. Yarns: The Basic Components

The fundamental properties of the polyester fibers determine the cloth’s potential.

- Tenacity: The raw strength of the yarn—its resistance to breaking under tension.

- Modulus: The critical metric for cruisers, measuring the yarn’s resistance to stretching under load (how much it resists elongation). Higher modulus means better shape retention.

- Denier: The thickness of the yarn. Thicker yarns offer better durability and UV resistance but can be less flexible. Finer yarns can be woven into tighter, lower-stretch fabrics but may be more susceptible to abrasion.

2. Weave: The Material Structure

How the yarns are woven together is just as important as the yarns themselves. In a sailcloth roll, warp yarns run lengthwise (parallel to the selvage, or edges of the roll), while fill yarns run perpendicular to the warp, across the roll’s width. In headsails and mainsails, the primary loads run along the luff and leech (vertically when hoisted), so fill-oriented cloth is used in cross-cut sails, with the stronger fill yarns handling these vertical loads and the warp yarns providing lateral stability. Sails with a tri-radial panel layout require their sailcloth to be strong in both the warp and fill directions. If the weave is not well-matched to the sail design and sailplan, the sail will not age well.

3. Finishing: Locking It All In

After weaving, the cloth undergoes finishing processes where heat, pressure, and resin coatings are applied—a process called calendaring (smoothing and stabilizing the fabric). This locks the yarns in place, setting the cloth’s final weight and stabilizing it against stretch. Premium finishes are engineered to maximize durability and performance, while inferior processes can use brittle resins that crack or fail to properly penetrate the weave.

Beyond the Basics: Specialty Hybrid Wovens

Hybrid wovens are built for offshore and high-performance cruising. By blending traditional polyester with high-tech fibers, they offer major gains in strength, shape-holding, and lifespan. These sails are stiffer, thicker, and far more durable than standard Dacron. The trade-offs are cost, weight, and reduced ease of handling—hybrid wovens are among the most expensive woven options, but the long-term durability can make them cost-effective for serious offshore sailors.

- Voyager (Nautosphere): A premium fill-oriented hybrid woven for offshore endurance, combining high-tenacity Dacron with Dyneema® yarns. Its proprietary construction method and innovative “Cold-Setting” finish deliver exceptional strength and stability.

- Hydranet® (Dimension-Polyant): A legendary radial cloth with Dyneema® threads woven into a Dacron grid. It offers dramatically increased tear resistance and longevity.

- Fibercon® Pro Vectran (Contender): This fill-oriented cloth incorporates Vectran yarns in the Fibercon polyester weave for their high strength and excellent UV resistance.

- Fibercon® Pro Hybrid (Contender): A radial hybrid that weaves Dyneema® yarns into Fibercon polyester, creating a strong, shape-retentive material.

Aesthetics: More Than Just White

While classic white dominates, modern Dacron offers options:

- Traditional Hues: Cream (“Egyptian cotton”), tanbark, and black are commonly available options.

- High-Visibility: Storm orange is crucial for safety in trysails and storm jibs.

- Fun Colors: Lightweight Dacrons for dinghies and daysailers are often available in red, blue, green, and yellow.

Note: Colored Dacrons are typically offered in a limited range of weights. Always confirm availability and suitability for your specific needs.

A Look at Dacron from Leading Manufacturers

At UK Sailmakers, we source Dacron from three leading suppliers: Dimension-Polyant, Challenge Sailcloth, and Contender Sailcloth. Each offers a broad range of quality options, from price-performing to premium and specialty hybrid materials. Their selections include a wide range of cruising and racing Dacrons, recycled options, and colored Dacrons, ensuring we can match the right material to your boat, rig, and sailing goals—whether you’re cruising, racing, or heading offshore.

The Bottom Line

Two sails may both be built using “7 oz. Dacron”, but their performance and longevity can be worlds apart. The choice of yarns, weave, and finishing can be quite different between manufacturers and product lines.

When you get a quote, don’t just look at the price. Ask your sailmaker: “Which specific cloth are you using, and why is it the right choice for my boat and how I sail?”

At UK Sailmakers, we partner with leading cloth manufacturers to select the perfect material for your needs. We ensure your investment pays off in years of reliable performance and sailing enjoyment. Because not all Dacrons are the same, and neither are all sailmakers.

Understanding the differences in Dacron sailcloth will empower you to make informed decisions for your next sail purchase and help you Sail with Confidence.